Toolpath simulation options give the machinist the ability to do a step-through simulation and review each operation at the machine, without the need to walk the machine through each cutting step or dry-running the program. In addition, the MBD and PMI data can be viewed, searched and filtered. They can also take linear, radial, angular, and area measurements. They can rotate, zoom, pan and section view the model. With the complete CAD viewer included, they can display the native design model with GD&T dimensional information and annotations of the 3D part model. When the machinist opens the file in the ShopFloor application, they have access to digital setup sheets, tool lists and the G-code program to help in the setup of the CNC machine.

#Is cam cnc full#

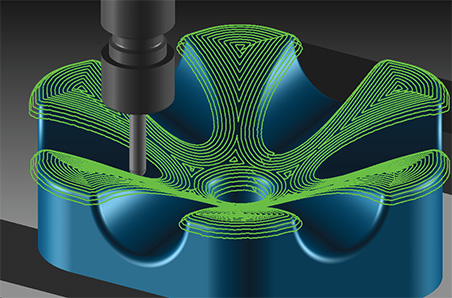

A PVC fitting mold is machined using full toolpath simulation in the new CAMWorks ShopFloor application.

#Is cam cnc pdf#

All the CAD/CAM data necessary to manufacture the part is included in one digital file, allowing companies to move beyond the use of 2D drawings or static PDF files.

Once the CNC programmer has completed the part programming in SOLIDWORKS CAM or CAMWorks, they publish the ShopFloor file for the machinist. ME: What’s new with your latest CAD/CAM software?īissell: HCL recently released CAMWorks ShopFloor, which delivers powerful CAD/CAM functionality to machinists without the need to have a full CAD/CAM system on the shop floor. This helps standardize and automate tooling and CNC programming processes. This allows manufacturers to capture their best practices and reuse them automatically. Taking this a step further, with the SOLIDWORKS CAM and CAMWorks Technology Database (TechDB), programmers can edit any of the automatically selected options and save them to a company-owned feature and strategy library.

#Is cam cnc software#

The databases of machining knowledge in the CAD/CAM software will select the appropriate tools (from a tool crib that matches the shop’s available tools), calculate the optimal feed/speed rates, apply the appropriate roughing and finishing toolpaths, and generate the NC code.

#Is cam cnc update#

There is also no risk in machining an obsolete part because the toolpaths are fully associative to the design model and they update automatically when a design or engineering change occurs.Īnother trend is automation tools, such as feature-based programming and knowledge-based machining, which have several benefits over operations-based CAD/CAM software. All the CAD and CAM data is stored in a single file, so there’s no need to maintain separate CAD and CAM files and no data translation issues. Teams can take parts all the way from conceptual design to a final product within the same software interface. With an integrated system, the CAD and CAM models become one. First, designers and the programmers use the same software environment to design the part, program machinable features, create the toolpaths and generate the NC code. However, manufacturing companies can take steps to gradually incorporate more automation into their machine shops and immediately see the benefits of using some of today’s advanced technologies.ĬAD/CAM software that is fully integrated-such as SOLIDWORKS, SOLIDWORKS CAM and CAMWorks-provides several benefits. Many manufacturing companies may see it as something that comes with a large price tag or requires a long, complex implementation. Implementing automation and moving to digital manufacturing can be daunting and has some specific challenges. Today’s technologies also make working remotely more feasible than ever, and the COVID-19 pandemic is hastening both the demand for automation and increasing the need for smart solutions in remote manufacturing. These encompass automation and digital transformation, giving manufacturers technologies needed to help them be substantially more productive. Marc Bissell: Some of the biggest technology trends are in smart manufacturing and Industry 4.0 initiatives. Manufacturing Engineering: What are the latest technical trends in CAD/CAM software development? New CAMWorks 2021 software shows a five-axis spiral swarf milling operation on an impeller.

0 kommentar(er)

0 kommentar(er)